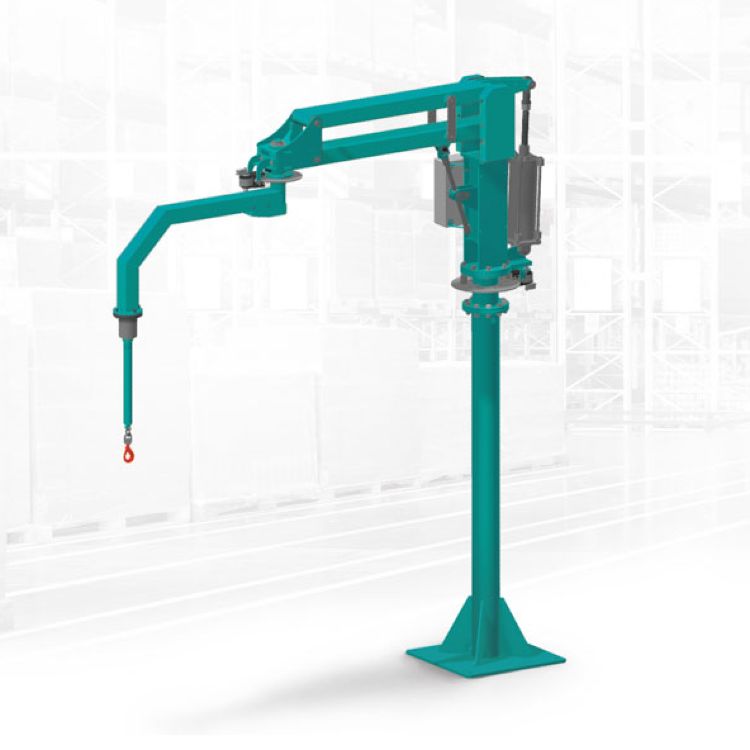

Rigid arm type industrial manipulators

INDUSTRIAL MANIPULATORS WITH RIGID ARM SYSTEMS – PRECISION, STABILITY, AND SAFETY

Industrial manipulators with a rigid arm system are specialized material handling devices designed for processes requiring precise load operation. Unlike cable-type systems, the design based on rigid arms allows for the total elimination of load swaying, ensuring the operator has full control over the object in every phase of movement.

Industrial manipulators with a rigid arm system are specialized material handling devices designed for processes requiring precise load operation. Unlike cable-type systems, the design based on rigid arms allows for the total elimination of load swaying, ensuring the operator has full control over the object in every phase of movement.

The SIGMA SA offer includes a wide range of models adapted to diverse production needs – from light construction devices like the SIGMA XS, dedicated to fast operations, to machines for special tasks and heavy loads like the SIGMA XXL.

Products presented below are standard products.

Our team is able to adapt ordered equipment to your individual needs.

Load Stabilization and Zero Inertia

The greatest advantage offered by an industrial manipulator with a rigid arm system is the way the load is guided. Thanks to its compact mechanical structure, the device neutralizes the inertia of the transported element. This allows for the realization of tasks unattainable for other types of hoists:

- Stable positioning in all axes: The load remains motionless immediately after the operator stops, without the pendulum effect.

- Handling untypical loads: The ability to safely grip and move loads whose center of gravity is significantly shifted relative to the gripper axis.

- Advanced operations: The rigid arm enables rotating, tilting, and docking parts while maintaining ideal stability.

Designing Individual Solutions

Every production stage has its specifics, which is why designing individual solutions is a key element of our offer. Our engineers analyze your technological process to adjust the arm's reach, lifting capacity, and device functionality to the specific task. Thanks to this, the manipulator becomes an ergonomic extension of the operator's arm, increasing work efficiency and safety.

Mounting Options – Installation Flexibility

To ensure optimal work ergonomics and save space in the hall, we offer four main mounting variants for our manipulators:

To ensure optimal work ergonomics and save space in the hall, we offer four main mounting variants for our manipulators:

- Column Mounting: The classic and most frequently chosen floor mounting. It ensures the highest stability and allows for the use of the maximum arm reach.

- Movable Column Mounting: A solution for plants requiring flexibility. The manipulator is mounted on a base plate, which allows for easy relocation to another place in the hall using a forklift or pallet jack.

- Overhead Mounting: Mounting the device to the hall's supporting structure or ceiling. It saves valuable floor space and facilitates maintaining cleanliness at the workstation.

- Overhead Trolley Mounting: Integration of the manipulator with a rail system. It enables the handling of extensive work zones and the transport of loads along the production line.

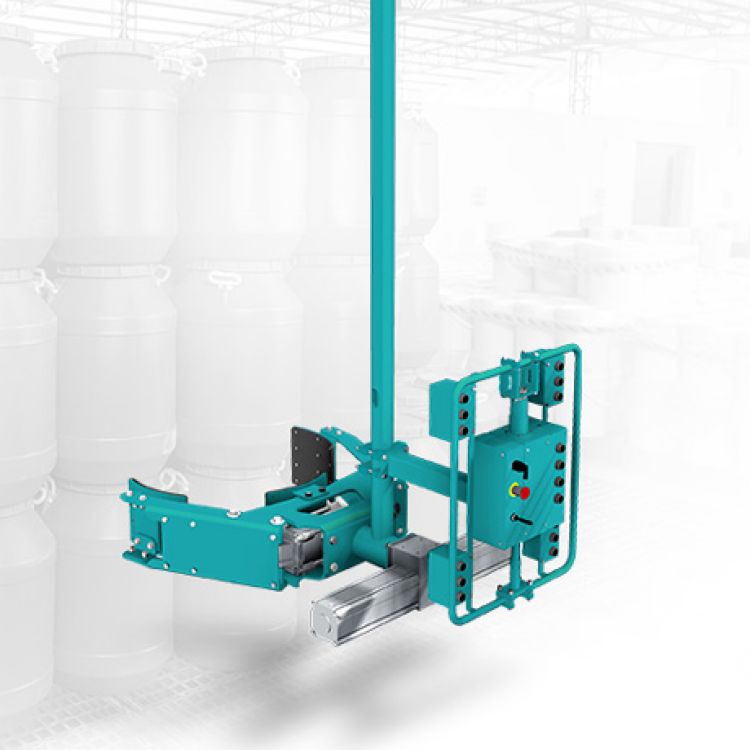

Manipulator Grippers – Precision Matched to the Part

Work efficiency depends on a secure grip. We design manipulator grippers dedicated to a specific load. In the case of rigid arms, grippers can perform complex functions, such as rotating the part (e.g., by 90° or 180°) or its precise positioning.

We use various gripping technologies:

- Jaw (clamping)

- Vacuum (suction cups)

- Magnetic

- Mandrel and Fork

- …

Advantages of Pneumatic Drive

Our manipulators are fully pneumatic. The use of compressed air is a guarantee of reliability and safety:

- Cleanliness: No hydraulic oils or lubricants, which is crucial in industries with elevated hygiene standards.

- Smoothness: Pneumatics ensure soft operation and easy load weight balancing.

- Safety: In the event of a power loss, safety systems lock the arm, preventing the load from falling.

Application – Manipulators for Heavy Tasks

Manipulators with rigid arm systems prove themselves wherever "hard" work characteristics are required. They are irreplaceable when handling heavy molds, castings, car body elements, or assembling mechanical components requiring a perfect fit.

At the same time, these devices pass the test perfectly with lighter loads that require stable guiding and safe transfer.

If you are looking for a solution that will eliminate the physical effort of employees and ensure 100% repeatability of movements – please contact us.

ALL MODELS - KEY FEATURES

| SIGMA XS | ||||

| Lift capacity [kg] | 50 | 90 | 125 | 180 |

| Lifting height range [mm] | 1700 | 1400 | 1100 | 800 |

| Minimal radius range Rmin [mm] | 850 | 700 | 600 | 500 |

| Maximal radius range Rmax [mm] | 3000 | 2500 | 2000 | 1500 |

| SIGMA S | ||||

| Lift capacity [kg] | 80 | 120 | 160 | 230 |

| Lifting height range [mm] | 1850 | 1600 | 1300 | 1050 |

| Minimal radius range Rmin [mm] | 1000 | 850 | 750 | 650 |

| Maximal radius range Rmax [mm] | 3500 | 3000 | 2500 | 2000 |

| SIGMA M | |||||

| Lift capacity [kg] | 100 | 150 | 230 | 330 | 470 |

| Lifting height range [mm] | 2300 | 2000 | 1700 | 1400 | 1100 |

| Minimal radius range Rmin [mm] | 1100 | 1000 | 850 | 750 | 650 |

| Maximal radius range Rmax [mm] | 4000 | 3500 | 3000 | 2500 | 2000 |

| SIGMA L | |||||

| Lift capacity [kg] | 200 | 280 | 400 | 530 | 700 |

| Lifting height range [mm] | 2300 | 2000 | 1700 | 1400 | 1100 |

| Minimal radius range Rmin [mm] | 1150 | 1050 | 850 | 750 | 650 |

| Maximal radius range Rmax [mm] | 4000 | 3500 | 3000 | 2500 | 2000 |

| SIGMA XL | |||||

| Lift capacity [kg] | 280 | 400 | 550 | 750 | 950 |

| Lifting height range [mm] | 2300 | 2000 | 1700 | 1400 | 1100 |

| Minimal radius range Rmin [mm] | 1650 | 1400 | 1250 | 1000 | 900 |

| Maximal radius range Rmax [mm] | 4500 | 4000 | 3500 | 3000 | 2500 |

| SIGMA XXL | |||||

| Lift capacity [kg] | 550 | 750 | 950 | 1200 | 1500 |

| Lifting height range [mm] | 1700 | 1500 | 1250 | 1100 | 950 |

| Minimal radius range Rmin [mm] | 1250 | 1100 | 1000 | 900 | 750 |

| Maximal radius range Rmax [mm] | 4500 | 4000 | 3500 | 3000 | 2500 |